Did you know that copper plays a vital role in the automotive industry, particularly in the electric vehicle revolution? In this comprehensive look at “how much copper is in a car”, we will explore its significance, its role in various components, and why it is essential for electric vehicles.

Key Takeaways

- Copper is essential for electric vehicles due to its superior conductivity, efficiency and role in green initiatives.

- Demand for copper from the automotive industry will significantly increase as electric vehicle sales rise.

- Recycling of copper from end-of-life vehicles provides economic and environmental benefits through cost savings, resource extraction reduction and waste generation reduction.

Copper Content in Various Car Types

Copper is an essential metal in vehicles, and its content varies depending on the type of vehicle. Electric vehicles harbor the most copper, overshadowing hybrid and internal combustion engine vehicles in this aspect. For example, an average car contains a minimum of 55 pounds of copper, while electric vehicles contain approximately 183 pounds.

Copper is a key ingredient in various car parts due to its exceptional electrical conductivity. Electrical systems, cooling systems, and mechanical components all incorporate copper to varying degrees. As the automotive industry continues to evolve, particularly with the rise of electric vehicles, the demand for copper is set to increase. Wood Mackenzie forecasts that the EV sector will need 250% more copper to power charging stations by 2030. This could have a significant impact on global copper demand.

Electric Vehicles

Electric vehicles are made up of several components, including:

- An electric motor

- An electronic controller

- A rechargeable lithium-ion battery

- A household plug

Some models may also feature a brass radiator for cooling. Copper is a vital component in electric vehicles, as it is required in substantial quantities for their batteries, motors, and charging infrastructure.

Electric vehicles demand a substantially higher amount of copper compared to their gasoline counterparts. Gasoline-powered cars on average require 20kg of copper per vehicle. Hybrid and electric cars, however, require much more, with hybrid electric cars requiring 40kg and fully electric cars needing as much as 80kg of copper. As these vehicles reach the end of their life cycle and become junk cars, recycling the copper content becomes essential.

Copper, used in electric vehicles, is found in various components such as:

- Electric motors

- Batteries

- Inverters

- Wiring

- Charging stations

These components are crucial for electric vehicle performance, making copper indispensable in the EV market.

Hybrid Vehicles

Hybrid vehicles integrate an internal combustion engine with an electric motor and battery, resulting in reduced fuel consumption and emissions. Copper is utilized in various components of hybrid vehicles, such as:

- Electric motors

- Batteries

- Inverters

- Wiring

- Charging stations

These components are all essential car parts produced by auto manufacturers.

Gas-powered cars typically need 20kg of copper, while hybrid electric cars require double that amount at 40kg. Fully electric cars necessitate the most, often requiring up to 80kg of copper per vehicle. Copper’s high electrical conductivity, durability, and malleability make it ideal for these components, ensuring optimal performance and efficiency in hybrid vehicles.

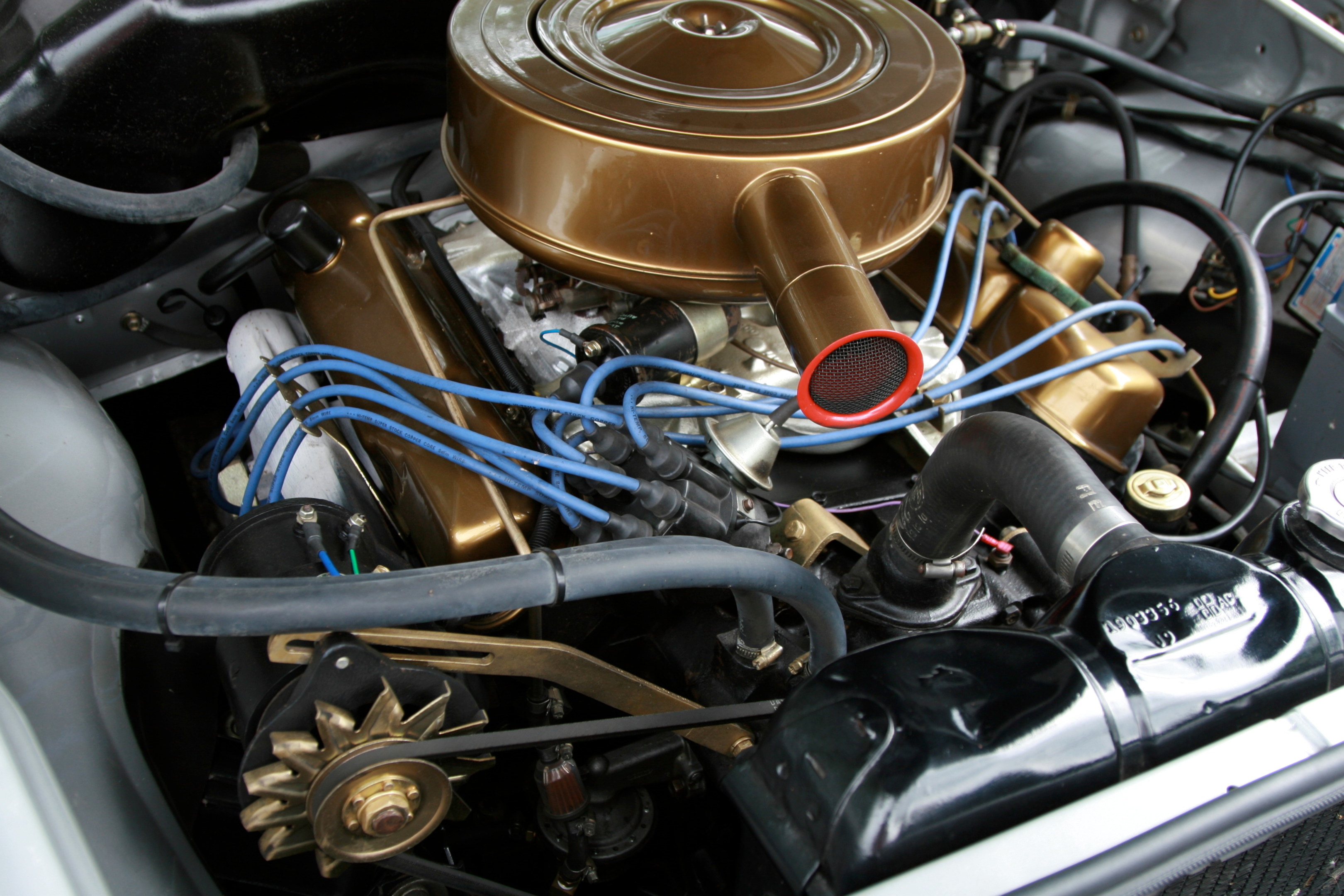

Internal Combustion Engine Vehicles

Internal Combustion Engine (ICE) vehicles, powered by an engine, generally house 20-50lbs of copper. This copper is utilized in components like:

- Power cables

- Motor coils

- Inverters

- Batteries

- Wiring

Copper is also used in the cooling systems of ICE vehicles in the form of copper radiators, which are favored for their outstanding thermal conductivity, facilitating effective heat transfer from the engine coolant.

Copper wiring plays a vital role in ICE vehicles, being utilized for power cables, motor coils, and inverters. The superior conductivity of copper makes it the ideal choice for wires connecting the chief components of the engine and air conditioning system. In comparison, aluminum cables are less commonly used due to their lower conductivity.

The Role of Copper in Vehicle Components

The exceptional electrical and thermal conductivity of copper render it invaluable in numerous vehicle components including electrical systems, cooling systems, and mechanical parts. For instance, in the electrical systems of vehicles, copper is essential for providing power to critical safety and comfort features. In cooling systems, copper’s high thermal conductivity allows for efficient heat transfer, preventing engine overheating.

Moreover, copper and its alloys are used in bearings and other mechanical parts due to their low wear and corrosion resistance, ensuring the longevity and reliability of vehicle components. In the following subsections, we will delve into the specifics of copper’s role in these various vehicle components.

Electrical Systems

Copper, due to its superior conductivity, is the go-to material for vehicle electrical systems, ensuring the smooth functioning of essential and safety features. In electric vehicles, copper allows for the production of smaller motor components that can be packed more closely together, leading to increased efficiency as less power is lost through poor conductivity.

Electric vehicles make extensive use of copper for their electric motors, batteries, and wiring systems. Copper is used for:

- Electric motors

- Batteries

- Wiring systems

- EV charging stations

- Superchargers

Copper wiring and cabling, made of high-quality copper wire, are essential for transmitting electrical power from the battery to the motor and other components. Furthermore, copper is utilized in EV charging stations and superchargers to guarantee electrical efficiency.

Cooling Systems

Copper is considered the optimal material for heat transfer through coolant in cooling systems. A vehicle’s cooling system typically comprises a radiator, water pump, thermostat, cooling fan, heater core, and overflow tank/coolant reservoir. Copper is advantageous in automobile cooling systems due to its superior thermal conductivity, corrosion resistance, and strength.

The advantages of copper’s high thermal conductivity in preventing engine overheating are numerous. Copper is capable of transferring heat into the radiator quickly, allowing for efficient cooling. Copper radiators are effective in preventing engines from overheating.

A copper-based cooling system in a car operates by utilizing copper components, such as the radiator and heat exchanger, to effectively transfer heat away from the engine. Copper has remarkable thermal conductivity, allowing it to absorb and dissipate heat in an efficient manner.

Bearings and Other Mechanical Parts

Copper and its alloys are employed in bearings and other mechanical components for their low wear and corrosion resistance. Copper lead, copper tin (tin bronze), and bearing bronzes are regularly employed in bearings and mechanical components of vehicles.

Copper promotes compatibility with soft alloy shafts, reduces friction in low-lubrication conditions, and possesses high mechanical properties. The use of copper-based bearing materials helps control adhesion and minimize wear.

Furthermore, copper alloy materials are renowned for their excellent mechanical and wear properties, making them suitable for applications in the aerospace and automobile industries.

Why Copper Is Essential for Electric Vehicles

Copper is indispensable for electric vehicles, owing to its superior conductivity, efficiency, and significant role in green initiatives and carbon neutrality. Governments and industries are increasingly focusing on:

- reducing greenhouse gas emissions

- achieving carbon neutrality

- driving the demand for electric vehicles

- driving the demand for copper

In the following subsections, we will explore how copper’s properties, including its cross sectional area, make it indispensable for electric vehicle components and infrastructure.

Conductivity and Efficiency

Copper, with its superior conductivity and efficiency, is the preferred material for electric vehicle components, guaranteeing optimal performance. Due to its high conductivity, copper allows for the production of smaller motor components that can be packed more closely together, reducing power loss and improving efficiency.

Furthermore, copper’s ability to conduct electricity is essential for an electric vehicle’s performance, as it allows for effective conversion of electrical energy into mechanical power. This results in enhanced efficiency and performance.

Additionally, copper’s conductivity has a positive effect on the lifespan of an electric vehicle’s battery, as it facilitates efficient electricity flow within the battery, reducing energy loss and optimizing the battery’s performance and lifespan.

Green Initiatives and Carbon Neutrality

There is a growing focus on green initiatives and achieving carbon neutral goals among governments and industries. Various governments globally have established targets for reducing GHG emissions, and numerous automobile manufacturers have declared that they will transition to exclusively producing hybrid or fully electric vehicles. Copper is essential for attaining carbon neutrality in the automotive industry, being employed in the fabrication of electric vehicles and renewable power-generating capacity.

Furthermore, utilizing recycled copper assists automakers in meeting their sustainability objectives while reducing the need for mining and processing new copper. Copper is also fundamental for electricity networks and is a cornerstone for all electricity-related technologies.

Future Projections

Anticipated trends suggest a steady rise in the adoption of electric vehicles, underscoring the significance of copper in the automotive industry. This growth is part of the electric vehicle revolution. By 2030, electric vehicle sales are projected to reach approximately 29.5% of all new car sales in the US, up from around 3.4% in 2021.

The increasing demand for electric vehicles will have a considerable effect on the copper industry. By 2040, copper demand is projected to rise by 53%, whereas supply is only expected to increase by 16%. This surge in demand for copper is driven by the electrification revolution and the growing market for EVs.

Recycling Copper from End-of-Life Vehicles

Copper recycling from end-of-life vehicles offers both environmental and economic advantages. Recovering copper from scrapped vehicles reduces the need for mining and processing new copper, conserving resources and reducing environmental impact.

In the following subsections, we will explore:

- The process of copper recovery from end-of-life vehicles

- The environmental benefits of recycling copper

- The economic impact of recycling copper in the automotive industry.

Copper Recovery

The copper recovery process from scrapped vehicles entails the following steps:

- Shredding the vehicles for material separation

- Extracting copper from the shredded materials

- Processing the extracted copper into distinct classes and grades

This process aids in recovering copper from the vehicles and contributes to the recycling of this valuable metal.

The efficiency of copper recovery from end-of-life vehicles has been found to range from 63% to 82%, depending on the approach and technology employed. There is scope to further increase the recycling of copper by recovering more copper-containing scrap and enhancing the recycling process.

Environmental Benefits

Copper recycling fosters a circular economy by reducing waste and enhancing sustainability. Recycling copper offers significant carbon emissions savings in comparison to mining new copper. The recycling process requires 85% less energy than primary production, resulting in a decrease of CO2 emissions.

Furthermore, recycling copper offers several environmental benefits:

- It diminishes the amount of waste that is disposed of in landfills.

- It can help decrease the ecological effect of the automotive industry.

- Utilizing copper scrap can reduce CO2 emissions up to 65%, making recycling copper a more energy-efficient and environmentally responsible option.

Economic Impact

Copper recycling has an economic impact, contributing to job creation, cost reduction for manufacturers, and potential profits for stakeholders in the recycling process. According to the Institute for Scrap Recycling Industries (ISRI), the scrap metal recycling industry has generated around half a million jobs.

Additionally, automotive manufacturers can realize cost savings through a 15% reduction in energy consumption related to copper production. Utilizing recycled copper can also assist automakers in achieving their sustainability objectives, particularly as they construct electric vehicles.

Summary

In conclusion, copper plays an essential role in the automotive industry, particularly in electric vehicles, due to its superior conductivity, efficiency, and contribution to green initiatives and carbon neutrality. As the demand for electric vehicles continues to rise, the importance of copper in the automotive industry will only grow. Recycling copper from end-of-life vehicles contributes to a more sustainable and environmentally responsible automotive sector, reducing waste and promoting a circular economy.

Frequently Asked Questions

What part of a car has the most copper?

The radiator and wires contain the most copper in a car, with an average of 55 lbs. found in total. Copper is used to connect the engine and air conditioning system of the vehicle.

How do you find copper in a car?

Copper can be found in many automotive components, such as wire harnesses, electronics, and motors, or as alloys in the aluminum of engine blocks or transmission housings, making it relatively easy to locate in cars.

Why is copper essential for electric vehicles?

Copper’s electrical conductivity, efficiency, and green initiatives make it an essential component in electric vehicles, enabling carbon neutrality.

What are the environmental benefits of recycling copper?

Recycling copper helps conserve natural resources, reduce greenhouse gas emissions, and reduce the amount of waste in landfills, all of which offer environmental benefits.

What is the efficiency of copper recovery from end-of-life vehicles?

The efficiency of copper recovery from end-of-life vehicles is promising, ranging between 63% and 82%.

Who We Are

Who We Are Coverage Area

Coverage Area Donate

Donate