If you’ve ever pondered the question, “how much copper is in a car?” you’ll find that the average car contains about 20kg (44 pounds) of copper, with that figure jumping to between 40kg to 80kg (88-176 pounds) in electric vehicles due to their more complex electrical systems. This article delves into the specific uses and importance of copper in the automotive world, from traditional engines to the latest in electric and hybrid technology.

Key Takeaways

- The copper content varies significantly between different types of vehicles, with electric vehicles containing up to 183 pounds of copper, substantially more than the 20kg found in traditional internal combustion engine vehicles.

- Copper plays a critical role in various essential car components, including the electrical systems, cooling systems, and bearings. Its superior electrical and thermal conductivity as well as its corrosion resistance make it invaluable in vehicle design and function.

- The importance of copper in electric vehicles is central to their performance, enhancing conductivity and efficiency, and supporting the industry’s shift towards carbon neutrality and green initiatives. The future projects a significant increase in copper demand owing to the EV market growth.

Copper Content Breakdown: A Closer Look at Different Vehicle Types

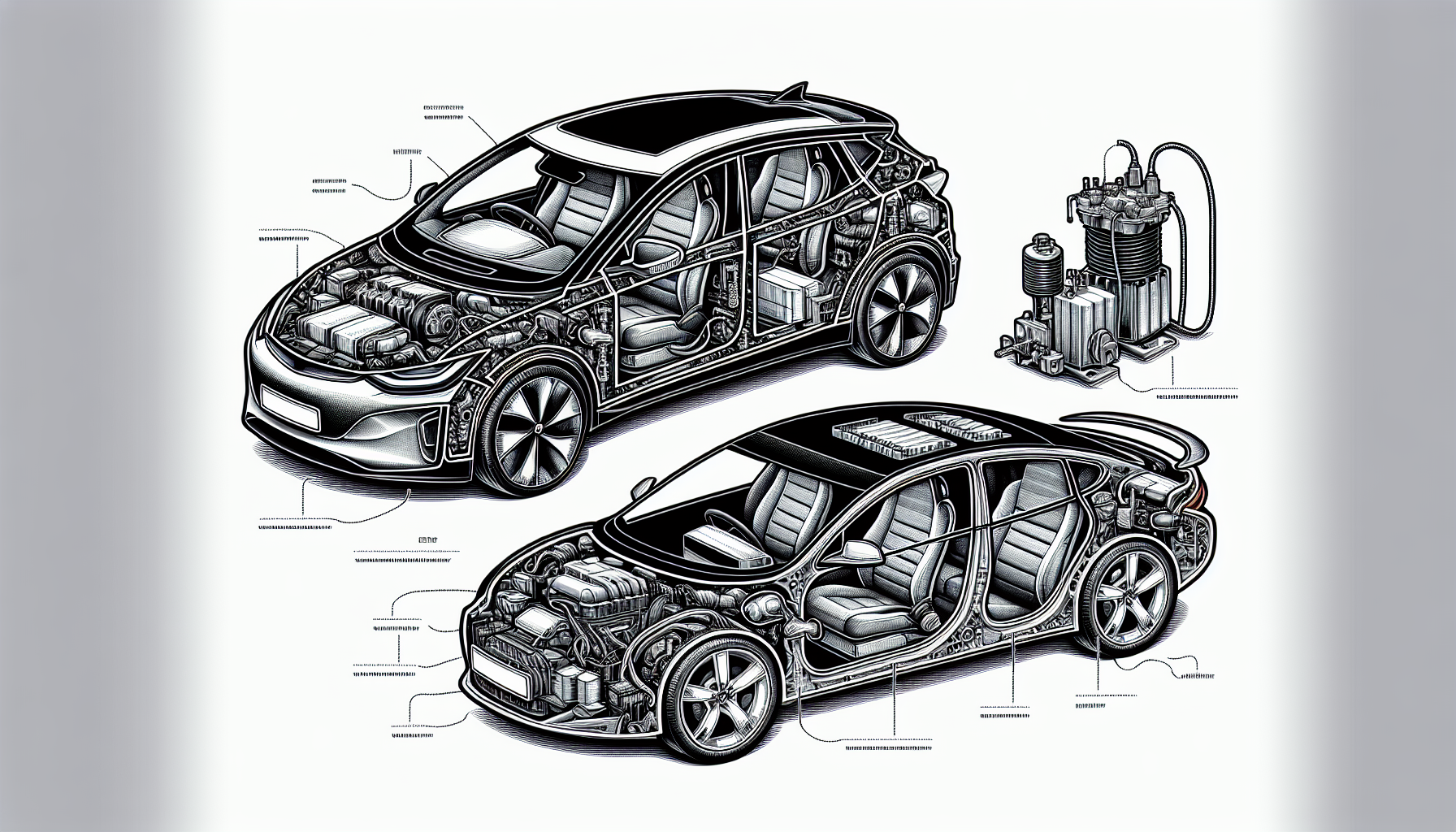

As we shift gears and delve into the composition of various vehicles, it’s clear that copper is more than just a mere component; it’s a versatile player essential to the functionality and efficiency of these mechanical marvels. The amount of copper wire, copper wiring, and copper alloys found in vehicles can be as diverse as the array of cars themselves – from electric vehicle marvels to older vehicles with their unique demands. Each type of vehicle has a tailored amount of copper, tailored to enhance performance and longevity.

Electric Vehicles

Electric vehicles are the avant-garde of the automotive industry, pushing boundaries with energy-efficient solutions and innovative technology. At their core lies copper, in amounts that dwarf the metal content in average cars. Picture this: an electric vehicle can house up to a staggering 183 pounds of copper. This hefty copper content, comprising electric motors, batteries, and a network of wiring systems, is the powerhouse behind the car’s ability to harness electrical energy and transform it into motion. And as the demand for EVs skyrockets, with an anticipated network of five million charging ports needed over the next decade, the copper within these vehicles becomes ever more critical to sustaining the surge of electrical systems.

Compared to the average car with a gasoline-powered engine, electric vehicles require significantly more copper, ranging from 40kg to 80kg, as opposed to roughly 20kg in older vehicles with internal combustion engines. This increase in copper is not just for performance; it’s a testament to the electric vehicle’s role as a harbinger of an energy-efficient future. The magic of the electric motor and the car’s ability to glide silently on the roads is indebted to the substantial amount of copper that lies within.

Hybrid Vehicles

Bridging the gap between conventional gas-powered cars and their fully electric siblings are hybrid vehicles, the automotive industry’s middle children, which are both energy efficient and innovative in their own right. Hybrids are no slouch when it comes to copper use; they boast approximately 40kg of the metal, doubling what you’d find in a traditional vehicle. This substantial use of copper is not by chance but by design, as the metal’s high electrical conductivity and durability make it a prime candidate for components like the electric motor and battery. In these vehicles, copper is not just a component; it’s a bridge to a more sustainable mode of transportation.

Imagine peeling back the layers of a hybrid vehicle and finding a world where copper is king. The metal’s malleability allows it to be shaped into car parts that are at the heart of the vehicle’s hybrid system. It’s a balancing act of power and efficiency, with copper playing a pivotal role in ensuring that the vehicle can switch seamlessly between its gasoline engine and electric motor. It’s about being more than half gas-powered or electric; it’s about being the best of both worlds.

Internal Combustion Engine Vehicles

The traditional internal combustion engine vehicle, the long-reigning monarch of the road, may not boast the same high copper content as its electric and hybrid counterparts, but it is by no means a pauper. These vehicles typically contain between 20 to 50 pounds of copper, a testament to copper’s enduring legacy in the automotive industry. The copper wiring in these vehicles is the lifeline for various systems, from the essential engine components to the creature comforts of the air conditioning system. It’s the metal that has powered generations of vehicles, ensuring that every turn of the key ignites a symphony of mechanical harmony.

In the engine bays of these older vehicles, copper stands as a guardian against the ravages of time, its corrosion resistance and heat transfer capabilities ensuring that the engine remains the beating heart of the car. It’s the unsung hero in the intricate dance of pistons and gears, allowing motorists to navigate the streets and highways with confidence. Copper in internal combustion engines is a legacy, an ode to a time when vehicles roared to life with the turn of a key and the power of a robust metal.

Copper’s Role in Essential Car Components

As we traverse further into the automotive realm, it becomes apparent that copper’s influence extends beyond the mere structure of the vehicle. This indispensable metal plays an essential role in chief components that define a car’s very essence. Think of copper wire and copper wiring as the nervous system of a vehicle, with wires connecting and transmitting signals and power throughout the body with the kind of efficiency that alternatives like aluminum and steel can only envy.

The corrosion resistance of copper alloys further bolsters the integrity of car parts, making them resilient against the elements and the test of time, while also contributing to essential safety features.

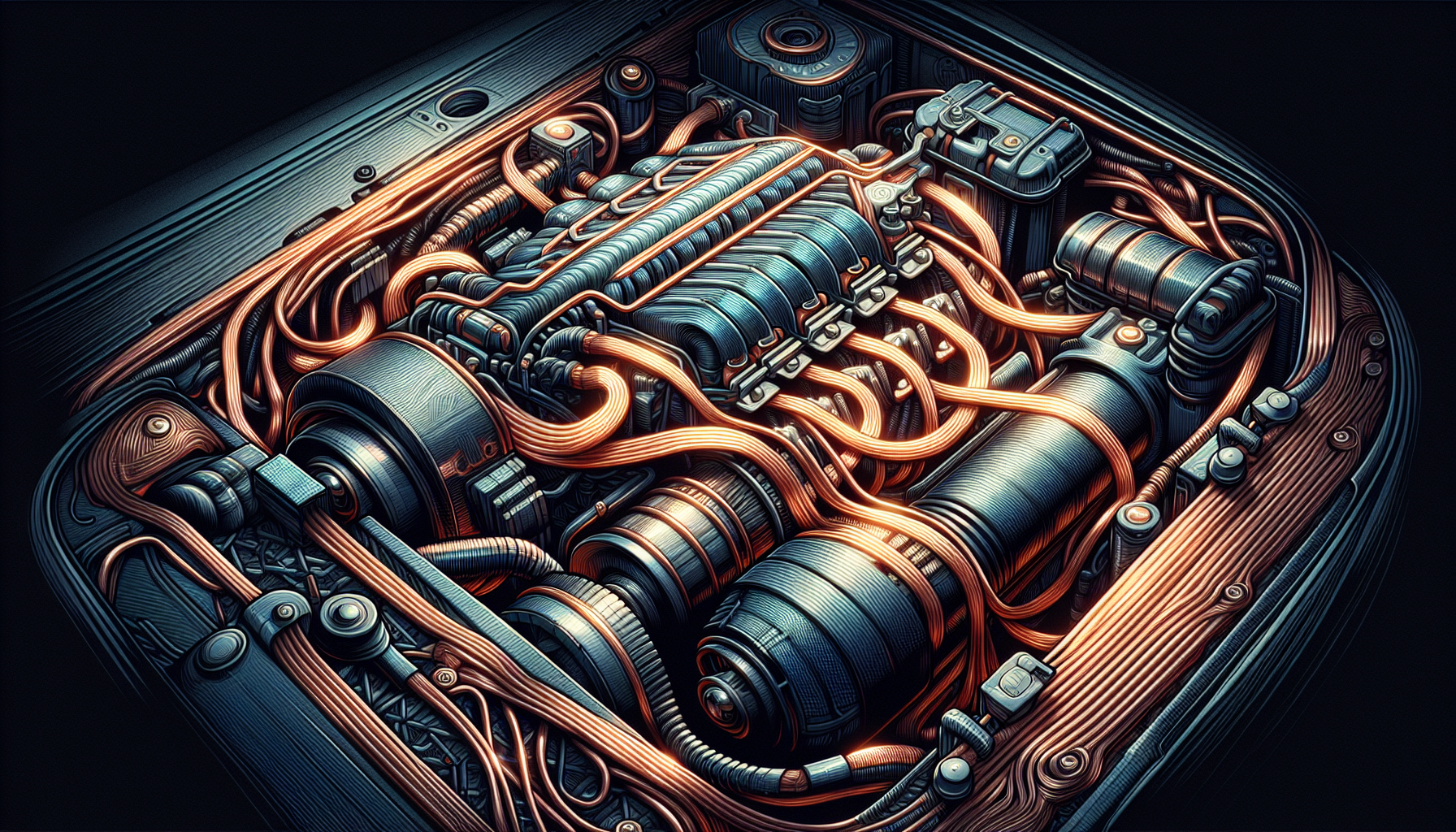

Electrical Systems

Dive into the heart of any vehicle, and you’ll find electrical systems pulsing with life, thanks to copper wiring. Copper’s unparalleled electrical conductivity allows for the creation of smaller motor components, enhancing the efficiency and lifespan of electric vehicle batteries. In electric and hybrid vehicles, this high conductivity isn’t just beneficial; it’s crucial for their operation. Components like inverters, charging stations, and electric motors all rely heavily on copper to function at their peak. The same goes for ICE vehicles, where copper is a key player in everything from the batteries that crank the engine to life to the air conditioning system that cools passengers on a sweltering day.

But the role of copper in electrical systems isn’t static; it’s evolving with the times. As vehicles become more advanced, with luxury cars boasting about 1,500 copper wires totaling a mile in length, the demand for copper is only set to increase. And with the advent of wound rotor synchronous motors using copper electromagnets, the amount of copper in vehicle motors is rising, showcasing the metal’s importance in the ever-advancing world of automotive technology.

Cooling Systems

Venture beneath the hood, and you’ll witness copper’s mastery over heat, a crucial element in any vehicle’s performance. Copper’s thermal conductivity is unparalleled, swiftly transferring heat from the engine coolant to the radiator, preventing the engine from overheating and ensuring a smooth ride. This high thermal conductivity, coupled with copper’s corrosion resistance, makes it a superior choice for manufacturers when designing cooling systems that are both efficient and durable.

It’s not just the ICE vehicles that benefit from copper’s cooling prowess. Electric vehicles, with their brass radiator systems, also harness copper’s thermal properties to maintain optimal performance and prevent the battery and electrical systems from overheating. The radiators and heat exchangers that make up these cooling systems are a testament to copper’s versatility and its ability to keep the vehicle’s temperature in check, mile after mile.

Bearings and Mechanical Parts

Copper alloys find their way into the very bones of a vehicle—its bearings and mechanical parts—where durability meets precision. These components must withstand the relentless pressure and friction of daily drives, and copper alloys rise to the challenge with their excellent bearing capacity and high resistance to wear. The inherent corrosion resistance of these alloys further ensures that the vehicle’s mechanical systems remain robust and reliable, even in harsh conditions.

The low wear and corrosion resistance of copper-bearing alloys contribute to the overall dependability of a vehicle’s mechanical systems, providing peace of mind to drivers and passengers alike. It’s these qualities that make copper alloys the material of choice for parts that must endure and perform, mile after mile, without falter. As you grip the wheel, take a moment to appreciate the unseen copper components that help guide you safely on your journey.

The Significance of Copper in Electric Vehicles

In the tapestry of the automotive industry, the threads of copper weave a story of innovation and progress, particularly within the realm of electric vehicles. The significance of copper in these futuristic machines is paramount, enhancing conductivity, efficiency, and supporting the green initiatives that are reshaping the way we think about transportation.

As we embrace a future where electric vehicles become the norm, copper stands as a symbol of the industry’s commitment to carbon neutrality and environmental stewardship.

Conductivity and Efficiency

The prowess of copper in electric vehicles is not just about its presence; it’s about performance. The metal’s high conductivity is a beacon of efficiency, ensuring that electric vehicles can:

- Translate electrical energy into kinetic energy with minimal loss

- Allow for smaller, more powerful motor designs

- Extend battery lifespans

- Enhance the vehicle’s range

- Reduce the frequency of charging stops

Copper’s electrical conductivity is the secret ingredient that makes electric vehicles not just viable, but preferable in an energy-conscious world.

But it’s not just about getting from A to B. Copper’s role in electric vehicles is about pushing the limits of what’s possible. By improving the conversion of electrical energy into mechanical power, copper ensures that electric vehicles not only match their ICE counterparts but surpass them in terms of performance and sustainability. It’s copper’s high conductivity that allows for the innovation of electric vehicle technology, leading to a future where the roads hum with the sound of progress.

Green Initiatives and Carbon Neutrality

Copper’s role in electric vehicles transcends mere functionality; it embodies the shift towards a greener, more sustainable automotive landscape. As the industry marches towards carbon neutrality, copper is at the forefront, facilitating the electrification of vehicles and the expansion of renewable power generation. It’s not just about the vehicles themselves but the infrastructure they depend on—electricity networks and charging stations that are the lifeblood of the EV ecosystem, all reliant on copper.

Moreover, the use of recycled copper is integral to the industry’s green initiatives, allowing manufacturers to reduce the environmental impact of vehicle production while still meeting sustainability targets. It’s a full-circle moment for copper, from powering the vehicles of today to being reborn in the vehicles of tomorrow, ensuring that the automotive industry’s path to carbon neutrality is both practical and profound.

Future Projections

As we peer into the crystal ball of the automotive industry, the projections for copper are as electrifying as the vehicles it powers. The insatiable appetite for electric vehicles drives a surge in copper demand, with each vehicle adding over 30 kilograms to this growing hunger. The numbers tell a compelling story: by 2030, the electric vehicle sector is expected to require a staggering 250% more copper to power the requisite charging stations. And with electric vehicle sales projected to account for nearly 30% of all new car sales in the US by the end of the decade, the importance of copper cannot be overstated.

The forecast is clear—a 53% rise in copper demand by 2040, with the automotive industry alone projected to call for 5 million tons of the metal by 2034. This soaring demand is a testament to the advancements in electric and autonomous vehicles and the relentless pace of innovation that defines the modern automotive industry. It’s a future bright with potential, powered by the humble yet mighty atom of copper.

Recycling and Recovery: The Importance of Copper in End-of-Life Vehicles

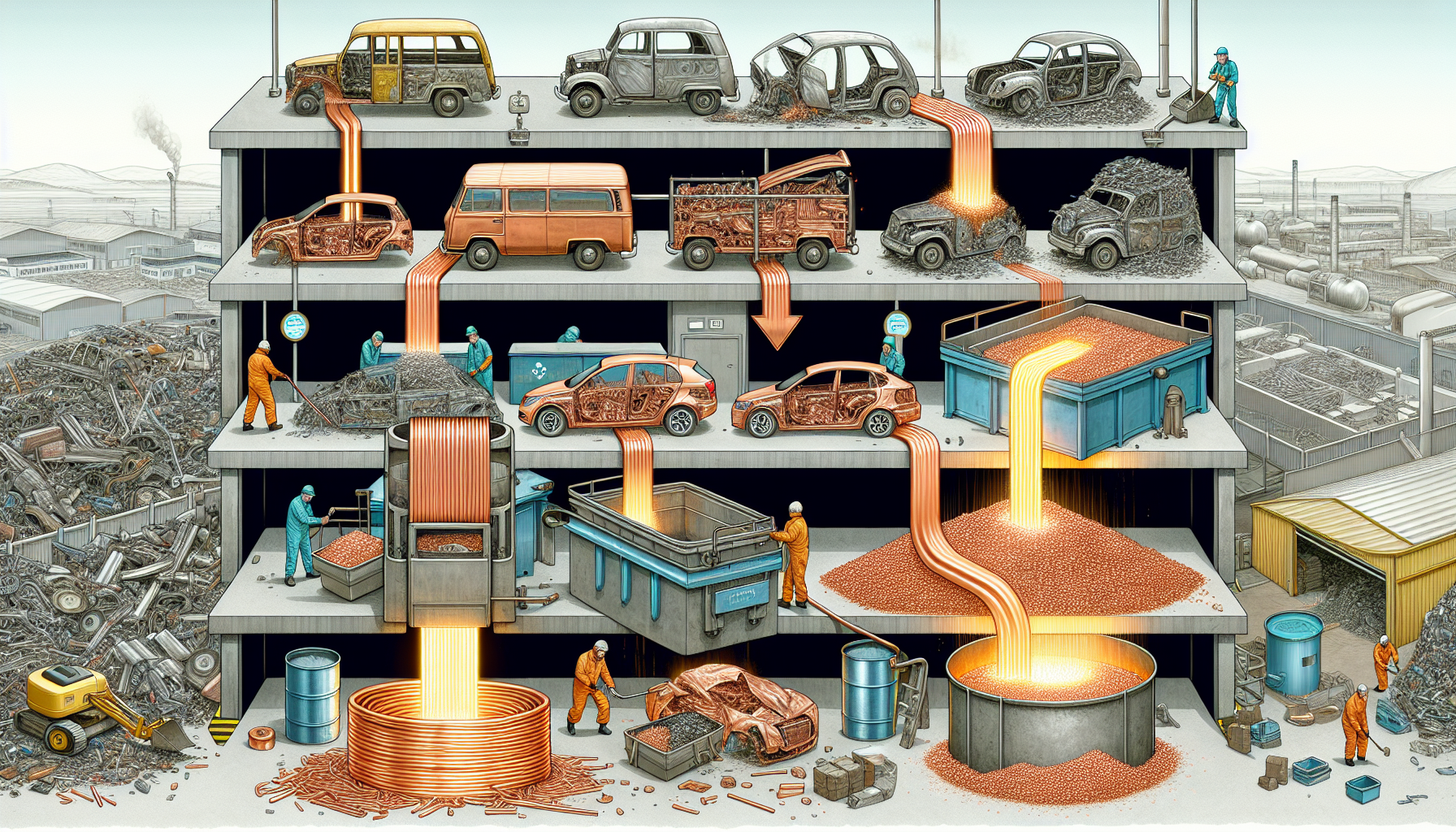

As vehicles reach the end of their road, the importance of copper doesn’t diminish; it takes on a new life through recycling and recovery. The sustainable practice of repurposing copper from junk cars not only conserves valuable resources but also offers a plethora of environmental and economic benefits.

By focusing on the recycling process, the automotive industry can continue to thrive without depleting the Earth’s finite resources.

Copper Recovery Process

The journey of copper recycling is a complex tapestry of activities, from the collection of older vehicles to the final stages of refining. The process is a marvel of efficiency, with recovery rates ranging from 63% to 82%, depending on the quality of the scrap. The meticulous steps of dismantling, sorting, and separation ensure that copper, whether it’s high-grade wire or lower-quality alloys, is given a second chance to shine. Regional regulations, such as EPA guidelines in the U.S. and EU directives, further refine the copper recycling process, aiming for high recovery rates that align with environmental objectives, such as the EU’s target of a 95% recovery rate by 2015.

The stakeholders involved in the copper recovery process play a symphony of roles, from original equipment manufacturers (OEMs) to dismantlers and shredding companies. Each contributes to ensuring that copper is not only recovered but also returned to the cycle of vehicle production, ready to take on the road once more.

Environmental Benefits

The environmental benefits of recycling copper from vehicles are as significant as they are diverse. By reducing the need for mining and processing new copper, we’re not just preserving natural resources; we’re also minimizing the harm done to our planet.

The process of recycling copper offers several benefits:

- It uses substantially less energy compared to producing new copper from ore, which reduces the environmental footprint.

- It helps the automotive sector move towards carbon neutrality and complements other environmental efforts.

- It ensures that copper remains an integral part of the industry’s future.

It’s a win-win scenario for both the environment and the industry.

Economic Impact

Beyond the undeniable advantages for our environment, the economic impact of copper recycling holds its own weight in gold—or should we say, copper. For every ton of recycled copper, a substantial amount of energy is conserved, translating to decreased operational costs for manufacturers and offering broader economic benefits. The variable energy savings achieved through processing different grades of copper scrap speak to the economic viability of recycling, which can fluctuate yet remains a financially sound practice.

The rising tide of the copper scrap recycling industry brings with it a wave of job creation in manufacturing, transportation, and waste management sectors. It’s a ripple effect – as the demand for copper continues to grow, so does the economic ecosystem surrounding its recycling. From the price garnered by scrap dealers to the cost savings for car manufacturers and the value it brings to buyers, recycled copper is a currency in its own right, fueling an industry that thrives on the cyclical life of this versatile metal.

Summary

As we journey through the world of copper and cars, it becomes evident that this metal is not just a conductor of electricity, but a conductor of innovation, sustainability, and economic growth. From the copper-rich electric vehicles driving us towards a greener future to the essential role copper plays in the components of all types of cars, its significance cannot be overstated. The recycling of copper from end-of-life vehicles only amplifies its importance, offering a sustainable solution that benefits both the planet and the economy.

In essence, the copper within our vehicles is a hidden treasure, a key element driving the automotive industry forward. So, the next time you’re behind the wheel, remember the copper that courses through your car’s veins, powering your journey, protecting your safety, and paving the way to a more sustainable world. Let this knowledge fuel your appreciation for the unseen yet indispensable role copper plays in every turn of the tire.

Frequently Asked Questions

Who gives the most money for junk cars?

Local junkyards and private buyers usually offer the highest payouts for junk cars, since private buyers may pay more for parts or personal projects, while scrapyards can pay more due to savings in dismantling and compacting services.

How much copper is typically found in an electric vehicle?

An electric vehicle typically contains around 183 pounds of copper, which is primarily used in the electric motor, batteries, and wiring systems.

Why is copper so important for the electrical systems in cars?

Copper’s superior electrical conductivity allows for the production of smaller and more efficient motor components, enhancing the performance and lifespan of vehicle batteries and electrical systems. This is why copper is so important for the electrical systems in cars.

What role does copper play in achieving carbon neutrality for the automotive industry?

Copper plays a crucial role in achieving carbon neutrality for the automotive industry by being essential in electrification of vehicles and expansion of renewable power generation, aligning with green initiatives.

How efficient is the copper recycling process from end-of-life vehicles?

The efficiency of copper recovery from end-of-life vehicles ranges between 63% and 82%, showing significant potential for resource recovery in the automotive sector.

For more information, visit https://www.carmula.com/

Who We Are

Who We Are Coverage Area

Coverage Area Donate

Donate